Legacy equipment failures shouldn't halt production. When original manufacturers discontinue parts or charge premium prices, replacement parts 3d design offers immediate solutions.

Womp transforms broken components into manufacturable 3D models within hours, not weeks.

Discontinued components: Original manufacturers cease production, leaving equipment vulnerable.

Premium pricing: Specialty parts command high prices due to low volume demand.

Lead times: Traditional manufacturing requires tooling setup and minimum orders.

Documentation gaps: Original CAD files unavailable for modification or reproduction.

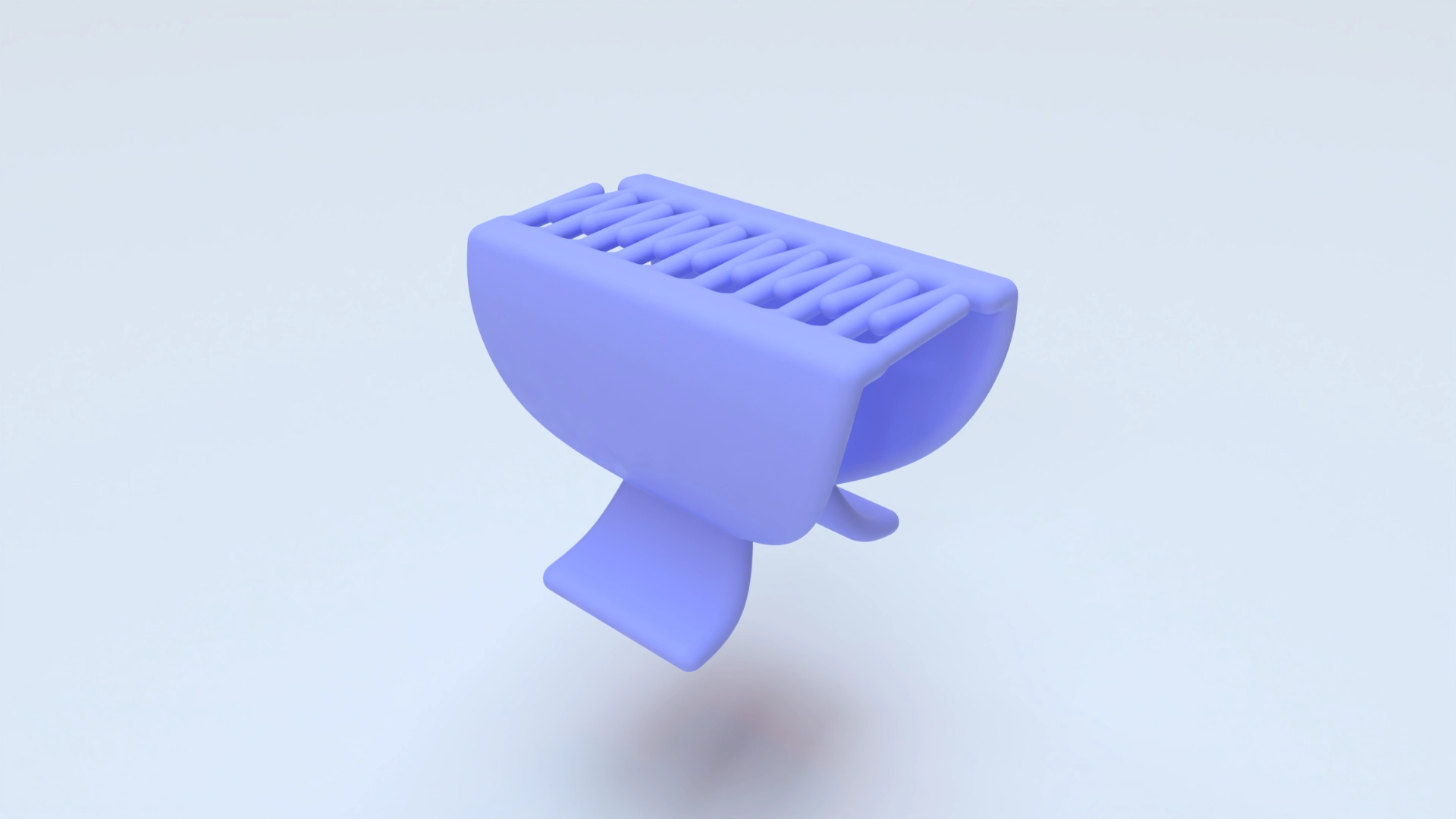

Digital recreation: Transform physical parts into accurate 3D models using measurement tools.

Design optimization: Improve upon original designs while maintaining compatibility.

Material selection: Choose optimal materials for specific application requirements.

SLA printing: High-resolution parts with smooth finishes and tight tolerances.

Material durability: Engineering-grade resins suitable for functional applications.

Same-day turnaround: Design to physical part in hours for critical equipment.

Global production: Manufacturing locations reduce shipping time for urgent repairs.

Industrial maintenance: Keep production lines running with custom-manufactured components.

Automotive restoration: Create unavailable parts for vintage vehicles and specialty applications.

Aerospace support: Manufacture certified replacement components for legacy aircraft systems.

Medical equipment: Maintain critical devices with custom-designed replacement parts.

Assessment: Analyze failed component for critical dimensions and material requirements.

Modeling: Create accurate 3D representation using Womp's advanced modeling tools.

Optimization: Enhance design for 3D printing while maintaining functional compatibility.

Manufacturing: Professional SLA printing with quality verification before shipping.

Traditional manufacturing costs:

3D manufacturing benefits:

Dimensional accuracy: ±0.1mm tolerance for precise mechanical fit.

Material testing: Verified mechanical properties for load-bearing applications.

Performance validation: Functional testing before deployment in critical systems.

Documentation: Complete design records for future reproduction.

Transform equipment downtime into rapid recovery with replacement parts 3d design. Start with Womp for immediate manufacturing solutions.

Related: Custom 3D printing services and manufacturing workflows.